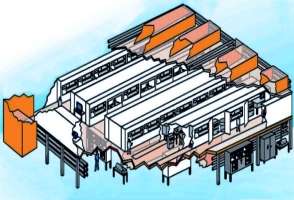

The PREMA SEMIC® chamber technology

Your ASICs will be produced on 6" or 8" wafers in a wafer fabrication plant in our facility in Mainz (Germany). Our fab incorporates the best concepts presently known, regarding flexibility, economy and process optimization. PREMA has developed the SEMIC® chamber (Standard Electronic and Mechanical Interface Clean Chamber). Autonomous local ultra-clean rooms, conceived and equipped with standardized electronic and mechanical components and interfaces for each of the numerous tools, and interconnected by a network, forming a highly flexible system of automated workstations.

A thorough compilation of production steps combined in one SEMIC® chamber guarantees optimum flexibility in the face of changing process demands and production volumes, providing a fast and reliable process flow at the same time. The status of each wafer can be monitored centrally at all times.

PREMA has developed the SEMIC® concept to comply with the increasing demands of semiconductor manufacturing, and to cope with the exploding costs connected with many technologies. Thus we have created a new leading concept for the design of wafer processing facilities.

Our customers profit from the PREMA production concept by achieving maximum economy, security of production, transparency of process flow and flexibility.