The path to an ASIC with PREMA

1. Free and Personal Consultation

You consider using an analog ASIC for your application, but don't know how to start?

In advance, we need some information from you about your requirements. If possible, please send us your requirements in form of technical specifications, a block diagram of the desired ASIC or a circuit diagram of an existing solution.

We will check feasibility and work out a proposal for the ASIC that we will discuss with you.

3. Circuit Design

Based on a mutually agreed specification, the design of the integrated circuit starts. In this process, simulation is an indispensable tool to verify the function within the whole range of operating conditions and process tolerances.

Then the circuit has to be layouted to represent the circuit in the physical layers of the production process. After checking compliance of the layout with the simulated circuit and the applicable design rules, we generate the data for the production of the photomasks.

We appreciate if you or an assigned design house can contribute in the circuit design. If you have this possibility, please discuss it with us. The development of the PDK is done with Tanner Software.

4. Prototype Production and Approval

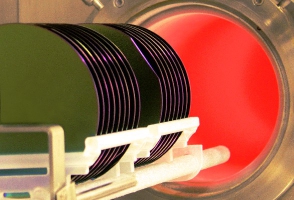

Prototypes are usually produced on multiproject wafers, but on the same production line that is also later used for series production.

These prototypes can be measured on wafer level, but also a limited number of parts in ceramic or plastic package can be provided for qualification in the application.

After passing all tests, we need your approval to continue to the next stage.

5. Test Development and Series Production

After approval of the prototypes, pre-series or series production of wafers will start.

In parallel, software and hardware for the automatic test on wafer level and of packaged parts is developed.

For plastic packaging, PREMA cooperates with partners in Germany and Asia.